- Use click plc as modbus server manuals#

- Use click plc as modbus server serial#

- Use click plc as modbus server software#

- Use click plc as modbus server code#

- Use click plc as modbus server series#

Success – This bit that we specify will turn on if the communication was successful and stay on until we enable the instruction again.Įrror – This bit that we specify will turn on if the communication was not successful and stay on until we enable the instruction again.Įxception Response (Error Code) – This will specify a memory location to store any error codes when communicating to the slave. Receiving – This bit that we specify will turn on when we are sending or receiving information through the communication port. Status Flags – These flags allow us to determine the status of our instruction. Word Swap – This is used when we read 32-bit registers from the Modbus slave and we need to switch the order in which the information is stored. In our case, we will read just the one register for the present value. Number of Master Addresses – We can enter the number of registers that we would like to read from the Modbus slave. Starting Master Address – This is where the information will be written in the click plc after reading the Modbus slave information.

Use click plc as modbus server code#

To read the PV value we must use code 4097. Starting Slave Address – This is the address that we wish to read from the remote slave device (Solo Temperature Controller) When we selected the Modbus function code to read the holding registers it limits the address that we can enter into this location for this function code. Our application will use Modbus 984 addressing which is patterned after the Modicon PLC addressing. In our case, we will select 03 – Read Holding Registers.Īddressing Type – We can select between Modbus 984, Modbus Hex, and Click Addressing. Modbus Function Code – We can select one of the four Modbus function codes. In our case, we have the node address set to 1.

Use click plc as modbus server serial#

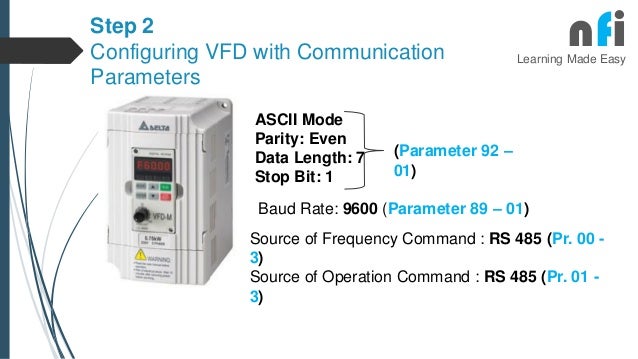

Slave ID of Serial Device – This is the node address of the slave that we wish to communicate. We can leave the advanced configuration to the default settings. Node Address 1 – 9600 baud, Even parity, 1 stop bit, 8 data bits. The parameters listed here must match what we set on the solo process temperature controller. We can set the protocol type of the communication port as well as all of the parameters. To change this setting go to Com Port Setup…Ĭom Port Setup… – This will open the Com Port Setup Details window. Protocol – This is the communication language that will be used on the communication port. Let’s look at the Click PLC Receive Instruction and the information that we need to provide.Ĭom Port – Click the arrow to display a list of the communication ports available on the PLC. A review of the Modbus RTU protocol can be seen at the following URL. A maximum of 32 devices (Nodes) on the network can communicate to the master. We can address up to 247 (Solo 1 to 247) devices on this master–slave protocol.

Modbus RTU will be the serial (RS485) method in which we will communicate between the Click PLC Port #3 and the Automation Direct Solo Process Temperature Controller.

Use click plc as modbus server software#

Our controller is now set to communicate.ĭownload the documentation and/or configuration and monitoring software at the following URL link:

We will leave the default unit number as 1. In the Initial Setting Mode we will change the online configuration to on and make the changes to the Modbus settings as follows: 9600 Baud, Even, 7 Data Bits, 1 Stop Bit, Modbus ASCII Format. Here is the way to change into the different modes in the Solo. The default setting is ‘Off’ for the On-Line Configuration. The solo process temperature controller needs to be setup before we can communicate to it. Additional information can be found at the following link. The first thing that we will do is set up the Solo Temperature Controller. Solo Settings – Click Send and Receive Instructions

Use click plc as modbus server manuals#

The programming software and manuals can be downloaded from the Automation Direct website free of charge.

Use click plc as modbus server series#

Previously in this Click PLC series we have discussed: Our example will read the current process (PV) value and write the set point value (SV) in the controller. We will demonstrate the Send and Receive instruction by communicating Modbus to a Solo Temperature Controller. Modbus serial communication (Modbus RTU) is a standard protocol used in many automation devices. The barcode will be read as an ASCII string in the PLC. Receiving ASCII can be used for connecting barcode scanners to the PLC. ASCII (American Standard Communication for Information Interchange) can be used to send to devices such as a printer. The communication method that you setup can be ASCII or Modbus. Receive and Send instructions will allow you to send and receive serial data to an external device.

0 kommentar(er)

0 kommentar(er)